Transparent GFRTP using PC alloy as matrix resin

FRP (or fiber reinforced composite) is generally opaque.

If FRP can be made transparent, for example, it will be possible to let in sunlight and see what is directly below even if protected by FRP.

This time, we will introduce the following paper that embodies transparent FRP with GFRTP, which is a combination of thermoplastic resin PC (polycarbonate) alloy and glass fiber.

Transparent FRP is conventionally heat cured

The key point of this initiative seems to be that transparent FRP was previously investigated using a thermosetting resin matrix, but it was realized using a thermoplastic resin.

In the case of using thermosetting resins, the following paper is one of the precedent cases.

Issues with FRP using thermosetting resin as the matrix resin are mentioned in the paper, including the difficulty of recycling and the length of the molding cycle.

When discussing the molding cycle based on injection molding, the difference between thermosetting resin FRP and thermoplastic is overwhelming.

However, when it comes to molding fairly large molded products or FRP with a large amount of reinforcing fibers, it is difficult to apply injection molding, and considering the recent evolution of matrix resins that are now capable of high-speed curing, the molding cycle is not always necessary. I don’t think that thermoplastic is superior to thermosetting in this regard.

Thermosetting matrix resins that can be cured quickly have been discussed in past columns.

*Related columns

There is no doubt that there are many issues with heat curing when it comes to recycling.

In any case, it must be kept in mind that there is almost no precedent for transparent FRP using thermoplastic resin as a matrix resin.

Issues with matrix resin for making FRP transparent are phase separation, crystallization, and refractive index mismatch

To make materials like FRP transparent,

It is necessary to overcome three assumed obstacles.

The three obstacles are;

Phase separation

Crystallization

Refractive index mismatch

It is said that it combines PC and PCL, which are highly miscible materials, to prevent phase separation.

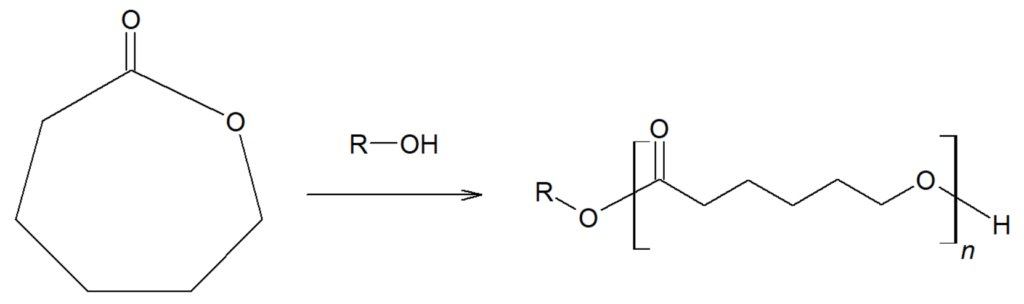

PCL (Polycaprolactone) is a polymer obtained by ring-opening polymerization of a cyclic compound called ε-caprolactone.

The reaction formula is shown below. Shows ring-opening polymerization with alcohol.

Drawn by FRP Consultant

So how do we overcome the challenges of crystallization and refractive index mismatch?

By increasing the proportion of amorphous PC, it becomes an amorphous alloy

The results were very interesting.

PC is amorphous, but PCL is a crystalline polymer.

Therefore, as long as PCL is added, there is a possibility that the properties of a crystalline polymer will be expressed.

The DSC chart is shown in Figure 2 of the paper, and it is clear that the peak of cold crystallization disappears when the proportion of PCL reaches 35wt% of the entire alloy.

This means that the alloy has become amorphous.

It is a common method to distinguish between crystalline and amorphous materials based on the results of DSC, which is a thermal analysis, so if you are not aware of this, it may be a good idea to know.

– Match the refractive index of glass fiber and matrix resin by changing the blending ratio of matrix resin

Another issue is the mismatch in refractive index.

The matrix resin used this time was

It is an alloy (molten mixture) of PC and PCL.

Since the refractive index of PC and PCL is higher and lower than that of glass fiber,

By mixing the two, the refractive index of the alloy can be matched to that of glass fiber.

It is stated that the refractive index for each D Line (589.3 nm) light source is as follows.

Glass fiber (E-Glass): 1.547

PC: 1.582

PCL: 1.466

The most important aspect of this paper is to solve the problem of refractive index mismatch by combining PC and PCL into an alloy.

Transparency is quantitatively evaluated using a Haze meter

Whether it is transparent or not is a qualitative judgment,

In this paper, we use a measuring device called a Haze meter.

The Haze value is the value obtained by dividing the diffuse transmittance by the total light transmittance, and the higher the transparency, the closer this value approaches zero.

Total light transmittance is the light that is received by the light receiver when the light that has passed through the sample hits the reference white plate, and diffuse transmittance is the light that is received by the light receiver when the light that has passed through the sample hits the reference white plate. It is said to be light diffused into.

What is interesting is that transparency is evaluated using diffused light rather than transmitted light itself.

I think the following videos and websites will be helpful in this regard.

Evaluation results using a Haze meter show that the haze value is minimized when the blending ratio of PC and PCL in the alloy is 65:35.

From the results so far, it can be said that an alloy formulation that is amorphous and can minimize the haze value has been clarified.

Reinforcing fiber of GFRTP uses chopped strands and roving cloth

A GFRTP flat plate is molded using an alloy with a fixed blending ratio as a matrix resin, and chopped strands and roving cloth as reinforcing fibers.

This is for producing test pieces for material property evaluation, which will be described later.

The former is extruded with reinforcing fibers, while the latter is extruded without reinforcing fibers, and the roving cloth is impregnated with the extruded resin under reduced pressure.

It says that it was molded from a flat plate of GFRTP.

It seems that some details have been omitted, focusing on FRP molding using roving cloth as a reinforcing fiber.

The purpose of evaluating both roving cloth and chopped strands is to confirm the extent to which the properties change as a result of physical processing such as crushing roving cloth into short fibers for recycling. .

I thought it was good that the motivation for industrial use was clearly stated.

– Material properties are high strength and high rigidity due to reinforcing fibers, but elongation at break is reduced.

As expected, it has been shown that combining with reinforcing fibers improves tensile strength and elastic modulus.

Compared to the values of PC:PCL alloy without reinforcing fibers (elastic modulus: 0.48 GPa, strength: 16.6 MPa), the elastic modulus and tensile strength of chopped strand and roving cloth are 4 times each (chopped strand: 1.79 GPa, roving cloth: 1.86GPa), 3 to 8 times (chopped strand: 54.1MPa, roving cloth: 26.6MPa).

Looking at the SS diagram, you can see the advantages of thermoplastic resin, and even with roving cloth, the elongation at break is close to 10%.

This elongation at break is very attractive from the viewpoint of high toughness.

However, according to the results of the Charpy impact test, in the case of chopped strands,

It should be noted that the Charpy impact value is significantly lower than that of the resin alone.

It is important to understand that while reinforcing fibers can significantly improve strength and modulus, they also increase brittle properties such as reduced impact resistance.

Please read the paper for details.

What should we think about from this paper?

Regarding the poor characteristics of GFRTP using chopped strands as reinforcing fiber

This time, we will talk about PC/PCL alloys that match the refractive index of glass fiber.

When chopped strand mat is used as reinforcing fiber, the elongation at break is significantly reduced,

Tensile strength that is only comparable to that of PC.

Results have shown that the Charpy impact value is significantly lower than that of resin alone.

The main causes are stress concentration at the ends of the chopped strand mat,

The paper states that this may be due to the chain of destruction that accompanies this.

I think this makes sense.

Stress transmission in FRP called Shear Lag model is mainly in shear mode.

In this idea, the reinforcing fibers cannot bear the load near the fiber ends,

It is also believed that shear stress increases in the vicinity.

I have covered the Shear Lag model in previous columns.

*Related columns

First FRP interfacial adhesion evaluation What is the fragmentation method? (Japanese only)

In addition to this, I think that the cause of the above phenomenon is:

“Insufficient impregnation of matrix resin”

For example, chopped strand mats are made up of multiple glass fibers.

It must be difficult for the thermoplastic resin, which has a high melt viscosity, to penetrate into this interior, and I think that the inside of the fiber bundle, which was not completely impregnated with resin, was the starting point for the failure.

Since glass cloth is a continuous fiber, the reinforcing fibers can bear impact and tensile stress even if the inside is not impregnated, which is probably why it achieved higher performance than resin alone.

Because the fiber length of the chopped strands is shortened to around 120 μm due to extrusion molding, it is possible that the fiber bundles are loosened by shearing force, so my hypothesis may be wrong.

But either way, it’s an interesting result.

New functionality of transparency

As mentioned at the beginning, the functionality of transparency seems to be intended to allow daylight.

Lighting, which has traditionally been handled by semi-structural members such as glass and resin,

The fact that FRP, a structural component, plays this role should be seen as a major step forward.

In applications such as drones where weight reduction is critical, the key is to make the structural components as simple and light as possible.

By using transparent FRP like this one in locations where you want sunlight to enter, it becomes possible to add rigidity to areas that did not previously exist as structural members, such as glass windows.

The above efforts lead to the reduction and thinning of structural members in other parts, making it possible to expand the interior space and reduce the weight of the aircraft.

Furthermore, FRP’s excellent corrosion resistance (chemical resistance) can be applied to the lighting windows of factories that handle corrosive gases and chemicals, and the pipes through which corrosive liquids flow to visually check the flow rate. Applicable laws may also be considered.

What did you think.

I think it is a very interesting result that transparent FRP was realized using thermoplastic resin as the matrix resin.

It may not be as transparent as glass, but its ability to pass light opens up a range of uses that were previously unimaginable.

I hope that transparent GFRTP will be adopted for various applications in the future.