Mizno produces high impact resistance Golf Shaft with CNT

New type of CFRP golf shafts from Mizno Co., Ltd. (http://www.mizunousa.com/) will come in the market in 2018. The shafts are the impact resistance modified by Carbon Nano Tube ( CNT ).

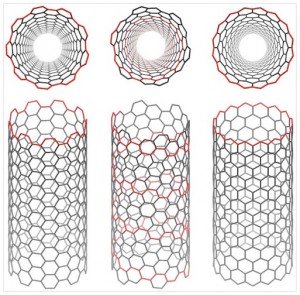

I have written the column regarding CNT here.

(The image above is referred from http://news.mynavi.jp/news/2012/07/20/003/ .)

Some of Japanese newspapers reported the news above. Mizno Co., Ltd. explained the reason of applying CNT to the golf shafts very clearly.

The dispersion of the small particles is always the problem. Mizno Co., Ltd. has successfully developed the new type of the surface treatment method to avoid the agglomeration.

The CFRP shafts with CNT are well modified regarding impact resistance, therefore Mizno Co., Ltd. could design the thinner shape and produce the new type of the shaft shape with the big impact head size to hit the balls more easily.

I am not so sure how to compare the impact resistance but they presented only the shaft failure impact speed comparison. It would be a little bit enough for me to understand it.

Anyway Mizno Co., Ltd. and NEDO ( New Energy and Industrial Technology Development Organization ) has developed the surface treatment technology for CNT dispersion for 2 years. Surface modified CNTs are expected to apply the wide range of the industry not only to sports but also to industrial product parts. Mizno Co., Ltd. has the group company of Mizno Technics Co., Ltd. (http://www.mizuno-technics.co.jp/) which produce vessels, tanks, or robot arms by CFRPs.

What shall we need to think about the press release above.

Surface treatment for CNT dispersion improvement

It is not so unique or new technology to apply the nano particles to CFRP to improve the mechanical or physical properties as you may know.

The most important point is that;

" The dispersion of the nano particle is achieved "

The detail points are not mentioned but the summary is;

" The new surface treatment technology enables to achieve the uniform dispersion by the relief of the molecular interaction and this technology can be applied for epoxy resin systems. "

This is mentioned in the press release of NEDO below.

URL:http://www.nedo.go.jp/news/press/AA5_100601.html

( English page is http://www.nedo.go.jp/english/index.html )

It is expected that this technology will also applied to thermoplastic resin systems. Of course the condition that the product design concept is reasonable shall be ready, CNT would have the big impact on the thermoplastic resin systems property improvement because the interaction between the thermoplastic resin and fibers is not stable. If the CNT application leads to the interaction improvement, this surface treatment technology is really precious in the FRP industries.

Design concept considering customer needs

Mizno Co., Ltd. is the company which do the design, development, and sales. It should be really profitable the company close to the customers proceeds the material development with NEDO, considering the customer needs.

Mizno Co., Ltd. does NOT present the CNT surface treatment technology by the very poor concept like

" Impact resistance is improved"

They presented the very clear concept that;

" The impact resistance enables us to design products thinner shape and it leads to the design flexibility as the result. This flexibility shall make it possible to achieve the additional commodity value."

This comment let us know their high stand view point and it would give me the very good impression.

Assembly makers close to the customer recognize the importance of the materials , and then they presented;

" Integration among material, design, and production is the most important factor to achieve the CFRP business. "

This point is pretty important in the whole FRP industry.

Problem of the press release

I shall say there still exist the problems.

The impact resistance is one of the static properties. But total designers should think the fatigue properties too.

Mizno Co., Ltd. and NEDO may have conducted the fatigue test but there is no mentioning about it in the release at least.

Another problem is that they focus only on Mechanical Properties.

Material / design / mechanical engineers tend to only focus on the mechanical properties.

The property is surely important for the products design but the physical properties are also important as same as the mechanical one.

I am also involved in the engineering/research projects of companies, research institutes, or universities in various countries. But most of the projects are inclined to focus only on the mechanical properties.

CNT has the unique properties regarding electric character, but there might exist different performance regarding thermal expansion, curing condition and so on.

Mizno Co., Ltd. is now proceeding the new approach in the FRP industries. This kind of the assembly maker, close to the customers, would be spread to the whole industries, I wish.