Resin impregnation to achieve the high performance of FRPs

Today I would like to talk about the basic content about FRPs, especially the important points to achieve their high mechanical and physical performances.

The high performance materials like CFRPs and also conventional GFRPs are getting the reputation to widen their applications in the purpose of light weight and high strength.

It would be however strange that very few persons answer the question;

"What is the most important point to achieve FRP's high performance?"

The understanding of it shall be the key factor to succeed the business in the field because many people here hardly have a chance to review it.

If I have a chance to mention the CONCLUSION first, the most important point is;

"The resins are properly impregnated in the fibers"

When I am the lecturer of the seminar, I often ask the attendees the quesion;

" What is the COMPOSITE?"

Can you answer the question above easily? If not, my column would help you something to understand FRPs.

80 percent of the attendees could not answer my question above actually as average. In other words, many people work in FRP field without the basic concept of the materials.

One of the reason above would come from the very few information regarding BASIC contents of FRPs.

The COMPOSITES are;

- They consist of two different materials which can be separated physically.

-

They show the higher or more unique performances which cannot be made it by each materials.

The two points above are the CONCEPT of the design of composites. We need to check the reason of the mixing the different materials because there is the INTENTION to do it and to make it.

FRPs are in the group of the composites, and they consist of fibers and resins.

To confirming the material design concept sometimes during your work, it may lead to the finding of FRPs.

Now I would like to start talk about the impregnation of the resins to the fibers.

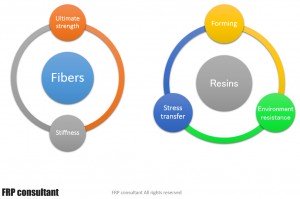

I often use the slide below when I talk about it in the seminars.

( The image above is licensed by FRP consultant. )

This image shows the role difference between the resins and the fibers.

Of course some factors shall be overlapped but roughly they can be separated as above.

The focusing points are below;

- Ultimate strength is determined by the fibers.

- The main role of the matrix resin is the TRANSFER of the stress.

The fibers shall have the resistance until the FRP's structure is fractured totally. The resins (Matrix resins) shall transfer the stress to the fibers.

In order to prompt the stress transfer from the resins to the fibers,

"The resin shall be impregnated in the fibers."

I can say one example of RTM ( Resin Transfer Molding ).

If the difficulties of the draping is overcome and the preforming is completed, RTM is the very good technology to make the complex shapes including the THICK components.

But the problems of RTM are;

"Have the matrix resins been enough impregnated? (Especially the thick one)"

The impregnation of the resins to the fibers is done very carefully from decades ago. This is the reason why the prepregs are prepared by the method of applying the low viscosity resins on the fibers with the high pressure system like double belt. The most important concept of designing the prepregs are; how to impregnate the resins inside of the fibers as much as possible. The impregnation condition shall be close to the ideal because the low viscosity resins are pressed on the single THIN carbon fiber layer.

So the FRP designers have the very high confidence to the prepregs even NOW.

Their confidence to the prepregs is based on;

"The resin impregnation to the fibers is prepared with very high quality levels."

The experienced FRP designers must pay strong attention to the resin impregnation conditions.

It is much more important than the questions whether the forming is possible or not.

In addition to the impregnation, the bonding condition between the fibers and the resins is also important. I will talk about it in another column.

I hope that you would remind the importance of the resin impregnation to the fibers in FRPs by the column.